产品中心

PRODUCTS

展厅实景

Exhibition Hall Scene

展厅实景

Exhibition Hall Scene

厂区实景

Factory Scene

企业实拍

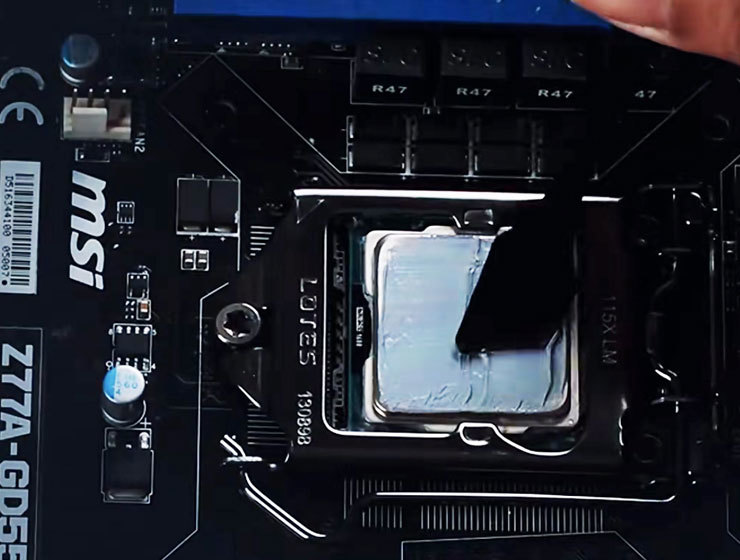

现代化的生产设备,精良的检测设备,为您的产品品质保驾护航

郑州粘接新材料有限公司

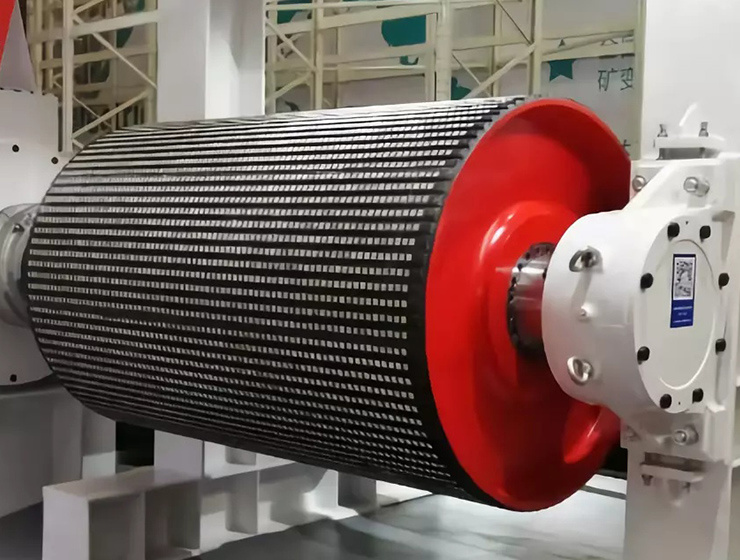

专注工业产品集中应用于矿业设备和输送系统的维护和保护

设备精良

公司是集工矿产品研发、生产、销售、技术服务于一体的企业,拥有精良的生产及检验设备

产品应用广

产品广泛用于洗煤、选矿、水泥、电力、冶金、机械、石化、建材等行业

不断研发创新

拥有一批化工化学品领域的人才,研发与生产并进;同时公司与高校建立了技术协作关系,在多方面有交流与合作

新闻资讯

NEWS

第21届中国国际煤炭采矿技术交流及设备展览会画上句点,这声聚焦煤炭采矿领域技术革新与设备升级的行业盛会,圆满落下帷幕。我们郑州粘接新材料有限公司作为此次展会中的一员,不仅有满满的收获,而且也获得行业伙伴的认可,粘接以诚心、诚信和真诚服务第一位,期待与您的再次相遇

输送皮带清扫器是一种用于清理输送带表面粘料的设备,其主要功能是清理上方的材料,防止材料堆积在输送带上导致堵塞。输送皮带清扫器在矿山、港口、化工厂等场所广泛应用,对于保证输送系统的正常运行和延长输送带的使用寿命具有重要的意义

“

在线留言免费获取产品报价

我们会尽快安排售后专员与您取得联系,帮助您找到符合您需求和目标的产品或解决方案。

”

郑州粘接新材料有限公司

地址:新郑市薛店镇中德产业园18栋

电话:0371-66631118 15638126963

邮箱:rmconveyor@aliyun.com

免责声明:本站部分素材来源于网络,如有侵权请联系我们,我们马上删除,谢谢。

微信搜一搜

郑州粘接新材料